Epsilon3 Helps Achieve AS9100 Certification

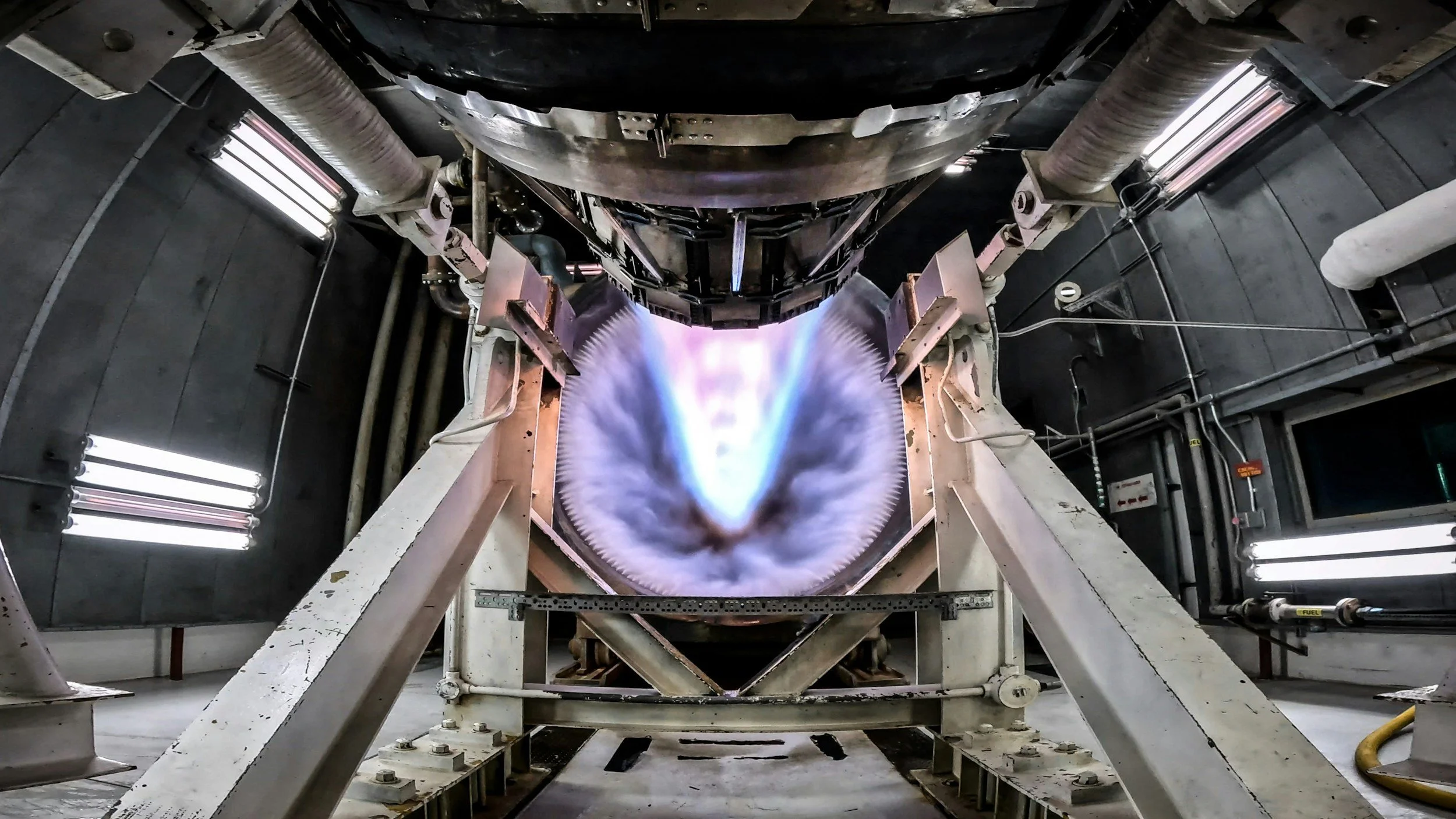

Quality assurance is mission-critical in the high-stakes world of aerospace and defense manufacturing. This article explores AS9100 standards and how Epsilon3 can help your team streamline the complex work required to achieve and maintain compliance.

What is AS9100 Certification?

AS9100 is a Quality Management System (QMS) standard specifically designed for the aerospace industry. This includes manufacturers of space, aviation, defense, and aerospace components. Certification requires following specific rules and guidelines that ensure everything related to the production and maintenance of aerospace products meets high-quality and safety standards. It’s built on the ISO 9001 standard but goes further to address the unique needs of aerospace manufacturers.

Why is AS9100 Certification Important?

Aerospace products need to be reliable, safe, and of high quality. AS9100 certification is critical because it:

Improves Product Quality: Helps companies consistently produce high-quality products with fewer defects.

Opens Market Opportunities: Many aerospace companies and governments only work with AS9100-certified suppliers.

Boosts Customer Confidence: Demonstrates to customers that a company is committed to quality and safety.

Ensures Regulatory Compliance: Helps companies adhere to laws and regulations, thereby avoiding potential legal issues.

Boosts Efficiency: Streamlines operations, reduces waste, and improves overall efficiency.

What’s Required to Get AS9100 Certified?

Getting AS9100 certified involves a detailed process:

Gap Analysis: Checking where the current processes fall short of AS9100 standards.

Documentation: Create procedures, processes, and policies that meet AS9100 requirements.

Implementation: Implementing these procedures and providing training to employees.

Internal Audits: Conducting audits within the company to ensure everything works as planned.

Management Review: Senior management reviews the Quality Management System (QMS) to ensure its effectiveness.

External Audit: A third-party auditor checks if the company meets AS9100 standards.

Certification: If the external audit is successful, the company gets AS9100 certified.

Maintaining certification requires continually adhering to these standards and regularly conducting internal audits and implementing improvements.

Epsilon3 Helps Achieve & Maintain AS9100 Compliance

Maintaining compliance with regulatory standards while scaling production is a complex and challenging task. Production teams using Epsilon3 benefit from our modern Manufacturing Execution System (MES), which was built with key Quality Management System (QMS) capabilities, including part and process version control, lot and serial number traceability, advanced issue tracking, and as-built Bill of Materials (aBOM) management.

Process Tracking & Documentation: Outline every step of the manufacturing process and keep detailed records of as-run procedures, builds, and tests.

Team Collaboration & Communication: Streamline QMS training and execution by centralizing information and providing real-time updates, ensuring consistency and visibility.

Quality Assurance & Control: Track the production and testing of your products to ensure they meet all standards outlined in your quality management plans.

Non-Conformance Reporting (NCR): Quickly flag and resolve part and process non-conformances to ensure your assembled parts and products always meet quality and safety requirements.

CAPA + Continuous Improvement: Identify quality issues, execute Corrective and Preventive Action (CAPA) plans, and drive constant improvement across your organization.

Reporting & Analytics: Data analysis tools enable you to make quick, informed decisions that help boost productivity and efficiency.

Conclusion

AS9100 certification is essential in the aerospace industry to ensure the highest quality standards. Achieving and maintaining this certification requires implementing systems to manage quality and enable continuous improvement. Epsilon3 can make this process much more manageable by providing procedure and part management solutions tailor-made for the aerospace industry.

With Epsilon3, manufacturers can optimize their operations to maintain compliance and stay far ahead of the competition.

About Epsilon3:

We’re a US-based software company on a mission to help teams manage complex operations in highly regulated industries like aerospace, defense, energy, robotics, and life sciences. Our web-based tools are used by industry leaders like NASA, Blue Origin, Redwire, AeroVironment, and Commonwealth Fusion Systems to plan and execute mission-critical procedures. The company and platform were purpose-built by engineering leaders from SpaceX, NASA, and Google.